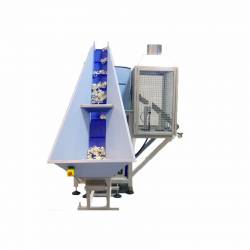

INDUSTRIAL FLAMEER FOR PRINTING AND STAMPING

Industrial flamers are on many occasions an essential element in the printing or stamping phase of objects in industrial production lines. They allow to pre-treat the surfaces to be silk-screened or pad printed to increase their surface energy, thus enhancing the retention and adhesion of the inks. The result with higher quality, resistant and durable serigraphs or pad prints.

Manual and automatic flamers from reference manufacturers

We have manual flamers for small or low-volume productions and automatic flamers, which are installed in industrial production lines and perform the pre-treatment of parts or objects in a fully automated way. Croma Ibérica has selected industrial flamers from leading manufacturers in the market to ensure that it provides its customers only with the highest quality solutions.

How does the flaming pre-treatment process work?

Above all, the flaming treatment is used to increase the adhesion of the ink on plastic surfaces. What industrial flamers do for the pre-treatment in screen and pad printing is to apply a flame on the surface of the pieces or objects of about 1800 degrees centigrade. During short-flame combustion, oxygen radicals are generated that break up the long-chain plastic molecules on the surface, increasing their polarity, resulting in an increase in their surface energy. This leads to an increase in the adhesion of the inks on said surface.

Let us advise you

We have extensive experience in the sector, both as manufacturers and distributors. We have great experts who will gladly help you in finding the solution you need. Do not hesitate to contact us!

We have different types of burners for flaming

Croma Ibérica has a series of burners for the industrial flamer, which will cover your needs.