Flamer MF400

The MF400 flamer is the most effective device when it comes to increasing the surface energy of objects, in order to optimize the adhesion of inks in industrial prints. The equipment has a closed air / gas circuit control, which provides a constant flame. Performing the surface treatment with the MF400 provides a higher quality in the final result of your product to be treated. In addition, the MF400 flamer only contains one control that reduces the risk of operator error, a fact that translates into total safety when handling the product.

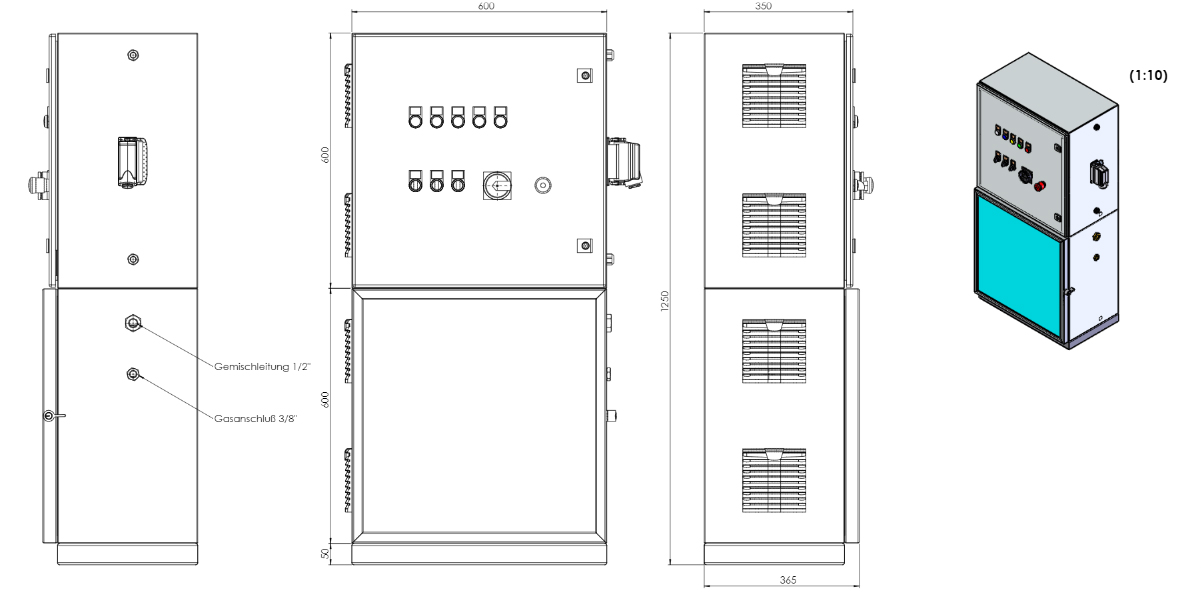

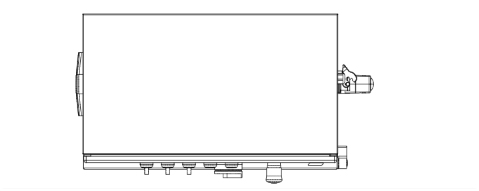

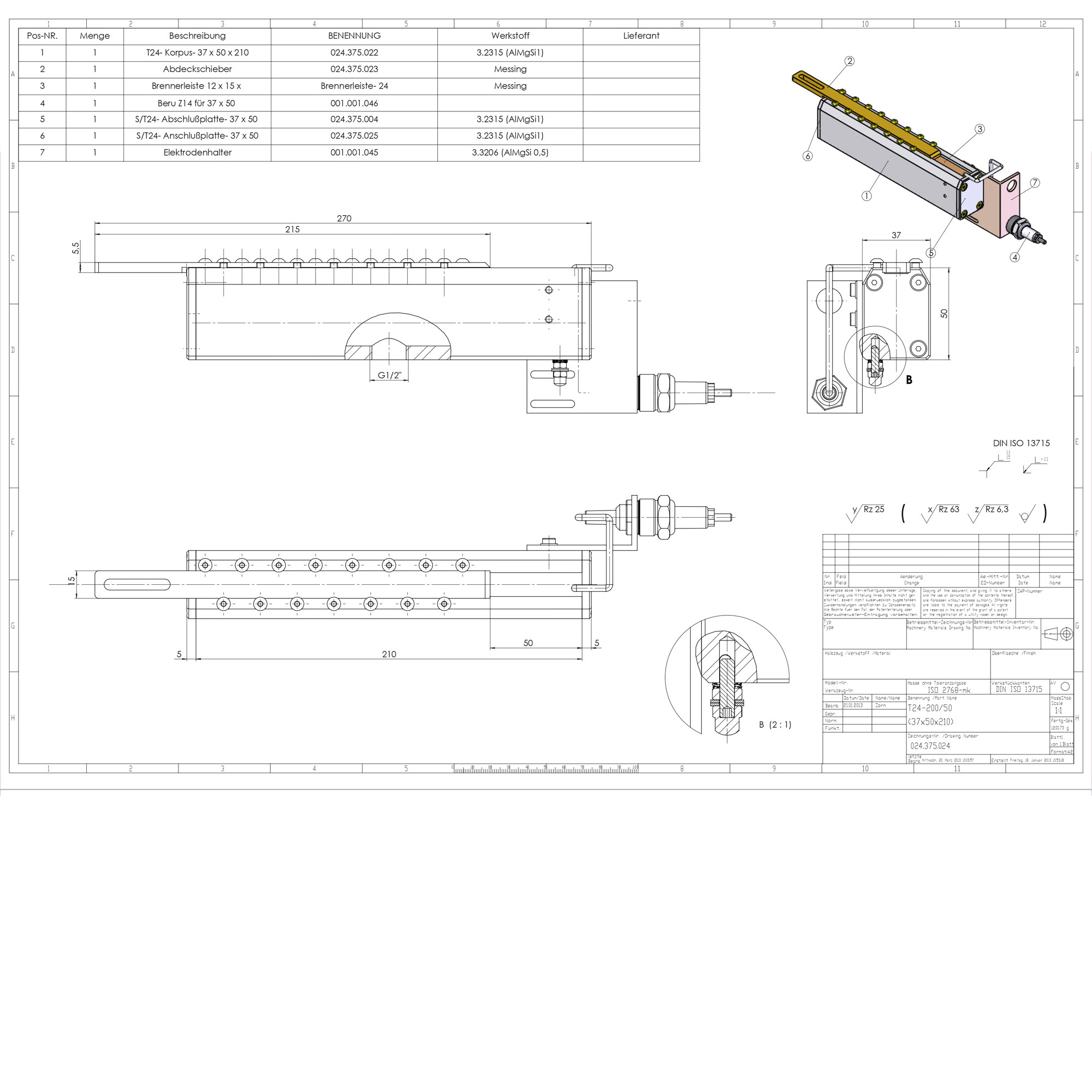

The MF400 flamer contains an electrical panel, which is used to control the automatic start and flame ignition functions. In addition, it has a mechanical cabinet from where it serves the compressed air. The MF400 also has the following features: safety valves, power regulation, automatic carburettor, pressure level controls and non-return valves. These characteristics make its operation optimal, efficient and fully automatic. It also has two types of burner with different sizes (100 mm and 200 mm) to adapt the process to different needs.

The industrial flamed operation consists of a flame that is projected on the piece to be treated. In this flame, which can reach up to 1800 °C during combustion, there is unconsumed oxygen (short flame), diffused oxygen in the hot flame from the environment and the combustion products (e.g. CO2, H2O) partially in the form active. These highly reactive radicals (e.g. O, OH) can break down long-chain plastic molecules on the surface and bind at the break points. In this way, polar parts arise in the molecules. Increases surface tension and wettability. The breakage of the long-chain plastic molecules allows the ink to bond better to the surface as well. The other processes that occur on the surface are a wrinkling of the surface and a certain cleaning effect. A wrinkle in microscopic dimensions, therefore not visible, leads to an enlargement of the surface and allows a better mechanical grip.

Data sheet

Loading...

Loading...

The MF400 is an industrial flamer that is used for surface treatment. This equipment has a compressor that generates air to feed the flame and carry out the flaming process. This device has a power 4 times higher than the MF100 flamer.