SURFACE TENSION TEST FOR PRINTING AND STAMPING

Measuring the surface energy of materials is a task of great importance for any printing or stamping job on objects, be it screen printing, pad printing or thermal printing, especially on low-adhesion materials such as plastics, metals or glass. You may find that upon starting the job you may find that the ink does not adhere well to the surfaces of the stamped objects, resulting in job cancellation and wasted time and money.

Avoid unpleasant surprises

To avoid this type of problem, we strongly recommend carrying out a test to check the surface energy of the surfaces to be silk-screened or pad-printed. In addition, with the test you can also determine if the parts or objects are properly free of debris, grease, oils, etc.

Simple and quick test

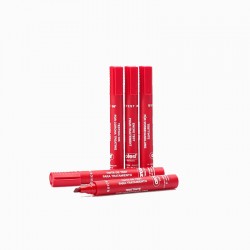

Measuring the surface energy of objects is very simple and fast. We simply have to apply a special ink using a brush or marker of a known surface tension. If the ink remains adhered without shrinkage for more than 2 seconds it means that the surface energy of the object is equal to or greater than the surface tension of the applied ink. Values are usually measured in mN / m. If this were not the case, we would use inks or markers with other surface tension values until we find the value where the ink remains without retraction for more than 2 seconds.

What is the appropriate surface energy?

In most cases, the following rule is fulfilled: The higher the surface energy of an object, the greater the retention of inks in screen printing or pad printing, etc. We recommend that through tests you determine the surface energy where the inks you use have better adhesion. From here, you will be able to determine if the rest of the objects in the following works will present good adhesion values or if it will be necessary to carry out treatments such as flaming, corona, plasma, etc.