10 reasons to stop outsourcing screen printing

10 REASONS TO STOP EXTERNALIZING AND DOING TEXTILE PRINTING YOURSELF

In this post we explain why every time you outsource you are losing money as well as putting the reputation of your business at risk.

¿What is screen printing? How does screen printing work? How to learn screen printing? How to make easy screen printing? How to screen print t-shirts? What do I need to do screen printing? How to set up a screen printing workshop?

Surely you have ever asked yourself any of the above questions. Within the textile printing sector, as in other sectors, we can subcontract services and jobs to other professionals, freelancers or companies. The main reasons for outsourcing processes are lack of knowledge and saving time. In the case of screen printing, many companies tend to outsource because it is a traditionally handmade technique, very dirty and requires a high learning curve. But with the arrival of Goccopro on the market, anyone without the need for experience can develop the printing process in a clean, easy and fast way.

If you still do not know the Goccopro method, before starting with the 10 reasons maybe you should watch this video:

1. Delivery times.

Tired of relying on supplier tempos? You can't be depending on someone else's delivery times! In your business you have to convey an image of seriousness and this involves delivering orders on time. Only by controlling the production yourself can you ensure the required delivery times. In this way you will be able to respond to urgent requests, adapting the reaction time to your needs without limitation; This will allow you to offer a plus in emergency services. The reputation of your business and the loyalty of your customers go through controlling this aspect. Are you really going to leave it to someone else?

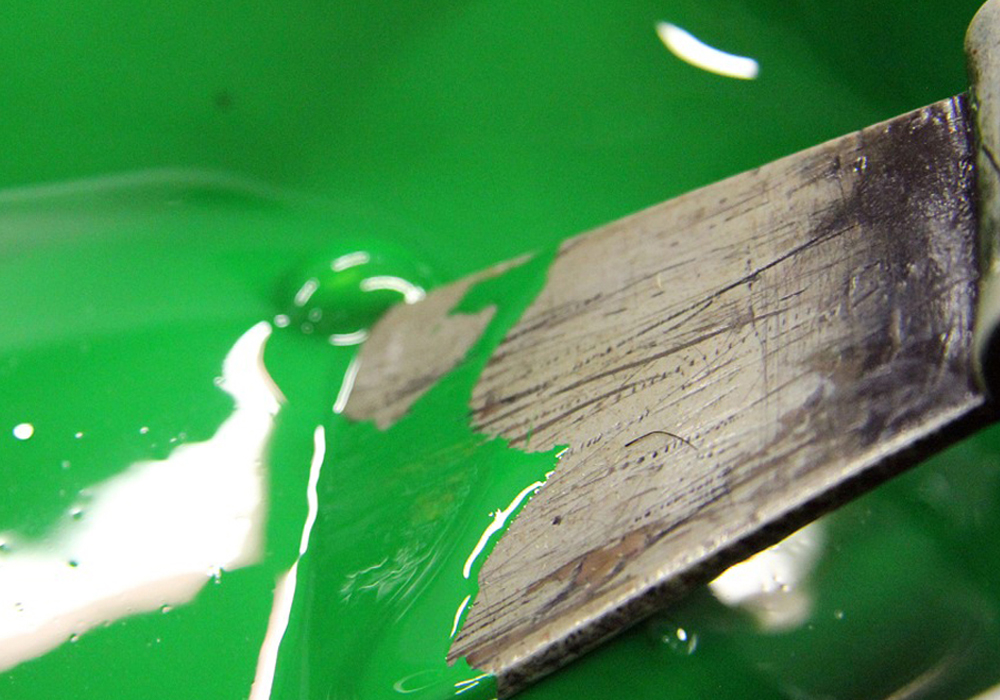

2. Clean environment.

Traditionally, handmade screen printing is a process that is associated with a dirty work environment and with the use of many chemicals to make screens. With Goccopro you will be able to create the screen in a totally hygienic way and then you will only have to apply the ink with the printing mechanism. This methodology will allow you to be able to produce in a modern and clean work environment, so that you can even do it in the office, in the back room, or at home, without the need to register chemical processes and without waste management.

3. More profitability.

Stopping outsourcing this service will allow you to better control production costs. By doing this work yourself, you will increase the commercial margin of your orders considerably and this will allow you to obtain more benefits. In addition, by not depending on a supplier, you can adjust the price policy and reaction times to your needs and thus be more competitive.

4. Quality.

The only way to control the quality of the product you deliver to your customers is to produce it yourself. When you outsource you do not know what products have been used, how they have been processed and consequently what durability and what guarantees they have. You must be the one who determines the quality standards and controls the production process, only in this way can you guarantee a quality product to all your customers. As with delivery times, quality is also at stake in customer loyalty and your reputation.

5. Ecolgical & healthy.

Textile printing with the Goccopro method is totally respectful of the environment and the health of the people who use it. Goccopro screens can and are used for printing food, cakes, chocolates, etc. given its clean and healthy composition. Traditional screen printing requires you to use highly polluting chemicals to make the screens, as well as a lot of water and a lot of energy to dry the screens. With Goccopro you can make the screens without water, without chemicals and without practically without energy. In addition, these teams have high energy efficiency, which means minimal energy expenditure. Welcome to ecological screen printing. You can also check our range of ecological inks.

6. Start producing without experience.

The secret of textile screen printing is to have a good screen. Printing itself is child's play. As we have commented previously, one of the main reasons for outsourcing screen printing is the difficulty in making the screens since they require a high learning curve and a great knowledge of the technique. But thanks to Goccopro technology making screens is really easy. Who does not know how to use a computer? If you know how to use a computer, you are already prepared to make screens with Goccopro, then you will only have to use the printing mechanism to apply the ink to the garment in question. In this way, with your screen printing workshop you can start producing and printing textiles -t-shirts, bags or countless objects- from the first day without the need for previous experience.

7. Personalized service.

Customer loyalty involves being able to offer them a personalized service and adapt to their needs. Apart from the immediacy and being able to respond to urgent requests, only by doing the textile printing yourself will you be able to offer a quality product at competitive costs. The success of your business depends on how you serve your customer. If you have autonomy and do not depend on any provider, you decide how and when you serve your client.

8. Modern.

Throughout human history, technology has always helped us improve production processes. Screen printing is a good example of this phenomenon. With the traditional method, creating a screen would take you about 45 minutes, in addition to all the time it would take to learn how to make screens and the high possibilities of having to repeat it or have to retouch. And all to achieve a quality not comparable to a Goccopro digital quality. Thanks to Goccopro's Japanese technology, this process takes approximately 2 minutes. It is not about being modern for its own sake. It is about making modern screen printing to be more competitive. Think about this reflection, How much is your time worth?

Your resources are limited, the profitability of a business is based on profitable and frequent sales, that is why you cannot dedicate unlimited time to production and make profitability unsustainable, because in that case, the more orders, the more hours dedicated and less benefits and the consequent loss of enthusiasm and commitment. Remember a single unprofitable order is not a problem but the more unprofitable orders you have before you will be ruined.

9. Small spaces

The price of the square meter in premises currently has a disproportionate cost, and registrations for economic activities are complex, irrational and expensive, especially if they are in shops with the doors open to the street for direct sales.

Today we adapt our workspaces to the different tasks that our day-to-day tasks require of us. Doing the textile printing yourself does not mean having to have a special space to develop this activity. With our printing workshops you will be able to work in reduced spaces because it is a totally clean process, without odor and without waste management. In this way you can produce in the office, in a store warehouse or even at home, as we show in the following video.

10. Differentiation

Finally, we want to tell you that there is only one way to do things, which is well done. Sometimes, the lack of means from an external provider means that you cannot get the finishes that your client expects. If you depend on another you can only always offer what they know how to do. On the other hand, if you control the whole process, you will get much more professional finishes and you will deliver the product as you want. In this way, you will give more added value to all your products, which will make you differentiate yourself from the competition. And you will once again have control over the destiny of your business and your future.

Have you had any questions or do you need more information? You can contact us by calling or by WhatsApp at 673 68 12 26 and we will be happy to help you find the solution that best suits your needs.

.jpeg)