Workshop Compacto 200

This workshop is the right solution for the manual production of textile screen printing in all types of spaces, also in confined spaces. Made up of the Goccopro QS 200 screen printer and the Ponny 5 drying tunnel screen printer, the compact workshop 200 will allow you to respond to all types of requests in a short space of time. Likewise, you can make designs in various colours (up to 4) in a printing area of up to 40 x 50 cm. All this with a high production capacity, reaching 100 garments / hour per operator. You will also get totally professional quality finishes, which will make you retain customers and stand out from the competition. Ideal for personalizing workwear, sportswear or advertising claim among many others.

Entrega en 24/48h*

Entrega en 24/48h*

Screen printing has always been associated with a traditionally complicated, slow, dirty process and with the use of highly polluting products. But now we are in front of a revolution thanks to the Japanese technology of Goccopro. Welcome to the new era where screen printing has become an easy, fast, clean and ecological process that anyone can carry out without the need for previous experience.

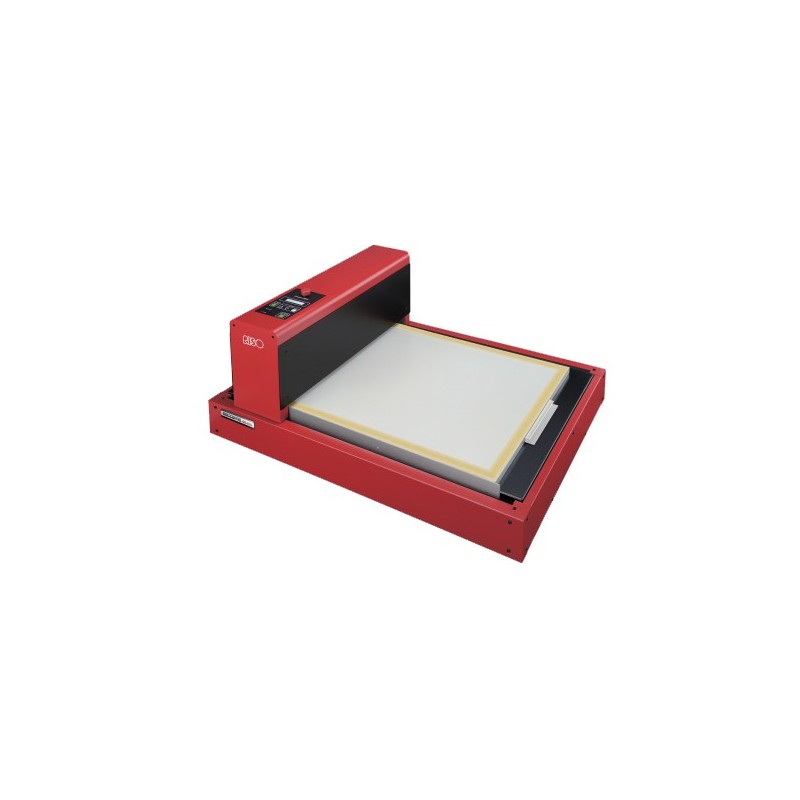

Goccopro 200: Machine with which you will create screens for serigraphs of various colors without difficulty, quickly and without the possibility of errors.

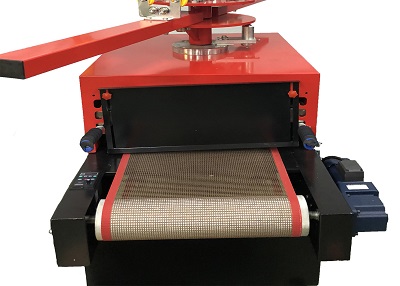

Ponny 5: Manual textile grab with four arms for printing up to four colours and a built-in drying tunnel.

This Kit will allow you to carry out an activity of textile screen printing and screen printing on flat rigid plastic objects in various colors in an easy and efficient way.

- Roll of fabric 120: 12 meters of mesh for Goccopro 100 to create HD screen printing (for approximately 30)

- Serigraphic accessory spider: Support for the serigraphic arm to be able to put the frame both horizontally and vertically.

- Goccopro frame: 28x40cm aluminum frame with quick fabric mounting system.

- Mounting strip: 2 sets of 10 m of rubbers for quick mounting of the mesh on the frame.

- Serigraphic scraper: For printing your design on the object to be silkscreened.

- Assembly tool: Utensil to give adequate tension to the silk screen.

- Roll of green tape: A roll of special Goccopro green tape to reinforce the fabric, protect the area to be printed or mask the fabric against attacks.

- Adhesive spray: Spray to adhere the objects to be printed on the octopus support.

At Croma Ibérica we offer individualized services for each client, adapting to all their needs, for that reason we offer specialized training for each client. This is a training course on printing with Goccopro, intended for all those who need to print, personalize or decorate any type of product and lack experience in the printing process using Goccopro.

Contact us: mkt@cromaiberica.com

Loading...

Loading...

This workshop is the right solution for the manual production of textile screen printing in all types of spaces, also in confined spaces. Made up of the Goccopro QS 200 screen printer and the Ponny 5 drying tunnel screen printer, the compact workshop 200 will allow you to respond to all types of requests in a short space of time. Likewise, you can make designs in various colours (up to 4) in a printing area of up to 40 x 50 cm. All this with a high production capacity, reaching 100 garments / hour per operator. You will also get totally professional quality finishes, which will make you retain customers and stand out from the competition. Ideal for personalizing workwear, sportswear or advertising claim among many others.

10 reasons to stop outsourcing screen printing

10 reasons to stop outsourcing screen printing