Structure in structural steel, electrowelded and varnished, they offer rigidity to the set so that the temperatures and work environments inside do not affect it over the years.

Modularized, removable for transport and easy to assemble, allowing it to reach any type of warehouse or workplace.

3 independent drying zones guarantee correct curing

The unit is equipped with 3 state-of-the-art electronic temperature controls, one for one of the drying stages, which offers a higher performance (of the order of 40% over the same traditional lamp) with its corresponding.

Likewise, it is possible to carry out a linear electronic adjustment of the power, without steps and a permanent display of the temperature parameters in each of the drying zones.

2 cooling zones, guarantee that no time will be wasted unloading and that the operators will be able to manipulate the parts without risk.

In this system, the traditional Teflon belt has been replaced by a steel sheet track, which guarantees in perpetuity the life of the conveyor under full working load with maximum weight.

Each of the drying areas has its own air recirculation in order to further homogenize the temperature and ensure that the forced draft of air reaches each corner on a regular basis.

2 cooling zones guarantee that the pieces will reach the end of the tunnel with maximum hardness and that the operators will work in a more suitable and efficient environment without having to withstand the extreme temperatures to which the products to be dried in the tunnel are exposed.

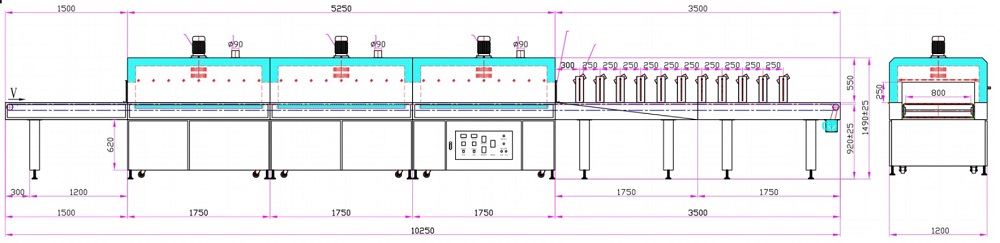

The conveyor belt of the TS 10300 measures approximately 920 mm, and the height of the mouth is 250 mm. The TS 10300 has a loading zone, which has a length of 1500 mm and 3 drying zones measuring 1750 mm. The conveyor speed of the tape can be chosen on the control panel. The type of belt is formed by a metal plate caterpillar.

Data sheet

Loading...

Loading...