Thanks to the fact that LED emitters only emit a single wavelength, we can have in a light source only the energy in the range necessary to activate the photoinitiators without having the disadvantages of parasitic radiation of other wavelengths, and infrared radiation that radically condition the use of halogen lamp systems in machines or close to people.

These characteristics make them highly efficient systems, since with 20 W of power they are more efficient than a 5KW halogen equipment. This UV-LED 56 unit, has small dimensions and high energy, concentrated in 56 mm in length, incorporates air cooling, which makes it ideal for manual use or for integration in machines where there is not too much space.

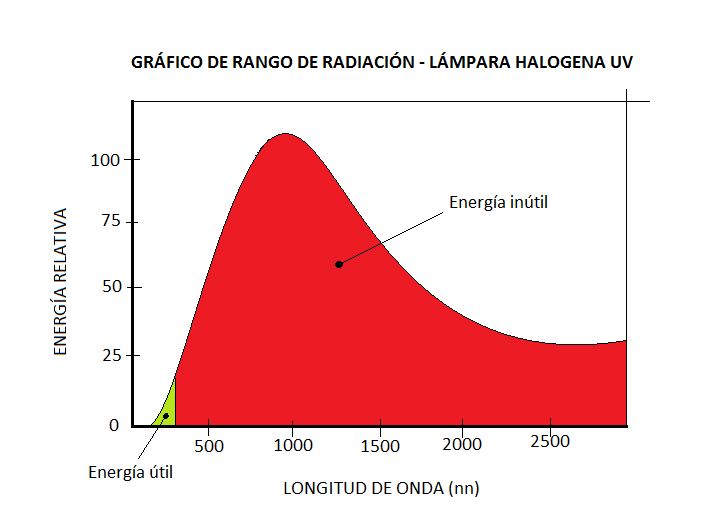

This is easy to understand if we look at the graph of a halogen UV lamp and see that the active wavelengths in most vats are close to 400 nm. See the small area identified as ultraviolet, all the rest of the emission of visible light and infrared light are parasitic and not necessary in the curing of inks.

Data sheet

Loading...

Loading...