The TS1800 is designed in order to offer an excellent option for professional screen printing curing at very low costs. Ideal for curing textile inks such as plastisol or modern water-based inks, as well as special inks for metals and glass up to 200º C.

The TS1800 comes with a very simple mounting system. Assembling the TS1800 will not require much time as, with the new mounting system, you only have to mount the lower legs.

A set of hinges and locks has been included in its design for quick access to the interior of the heat zone, thus facilitating maintenance and cleaning.

Equipped with modern 1 KW IR (Short Wave infrared radiation) lamps, it guarantees professional curing of textiles and all kinds of articles at a very wide temperature range.

The TS1800 motor incorporates a servo motor with electronic speed and reversal control and an industrial gear reducer.

The fibreglass conveyor belt with Teflon coverage is ideal for temperatures up to 200ºC and provides high tensile strength that guarantees long durability according to the most demanding industrial standards. The transport band is sewn with a removable closure for easy handling or replacement with another of different dimensions or characteristics.

Continuous electronic power regulation from 0 to 100%.

The TS1800 curing tunnel incorporates two highly resistant machined aluminium traction drums.

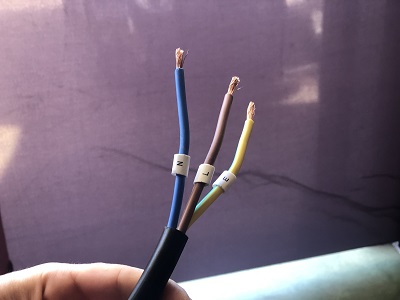

The connection of this drying tunnel is single-phase, compensated to 220 V.

Equipped with top quality industrial control elements.

Feet in structural tube with wheels with brakes for easy movement.

The TS1800 curing tunnel is served with the legs removed, fully wired. The whole set is supplied packed in a closed palletized wooden box. Means of transport and lifting of the package may be necessary for handling during transport (pallet truck, forklift, etc.). There is the option of supplying it assembled, although in this way the general dimensions increase and make the cost of transport higher and require some means of protection or additional packaging appropriate to each case.

This product is available in stock for immediate delivery, 12-24 h.

There is the possibility of acquiring the equipment assembly service. This assembly will always be carried out in our facilities and will cost €110. In this case, the disassembly and transport would be borne by the customer.

Data sheet

Loading...

Loading...

Electric drying tunnel for fast curing of water-based inks and plastisols. Ideal for textiles.

Delivery time: 6-8- weeks