The TS 2500 drying tunnel was born as an evolution of the previous smaller TS 1800, in order to offer an excellent option for professional screen-printing curing at very low costs. Ideal for curing textile inks such as plastisols or modern water-based inks, as well as special inks for metals and glass up to 200º C.

Equipped with modern 1 KW IR (Short Wave infrared radiation) lamps, it guarantees professional curing of textiles and all kinds of articles at a very wide temperature range...

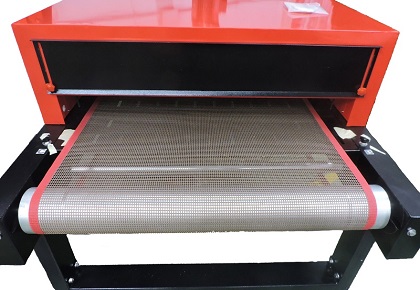

In its design and construction, special care has been taken of the solidity and durability of both the set and each of the vital parts:

A set of hinges and locks has been included in its design for quick access to the interior of the heat zone, thus facilitating maintenance and cleaning.

The TS 2500 allows you to configure the power in steps of 600W (single phase) or 1800W (three-phase), in order to be able to adjust the optimal power on each occasion. In addition, the TS 2500 drying tunnel is built in 2 mm sheet metal for maximum structural rigidity with an insulating layer 20 mm thick to guarantee the minimum dispersion of energy (heat) to the outside, so that consumption at the end of the day is the minimum necessary and make the tunnel more efficient.

To guarantee a homogeneous temperature over the entire surface, the TS 2500 curing tunnel is equipped with an internal air recirculation system by means of a turbine inside the tunnel, which is driven from the outside by an asynchronous motor. In this way the operation of the motor is guaranteed for life and minimum variations in the temperature inside the tunnel can be guaranteed.

The fibreglass conveyor belt with Teflon coverage is ideal for temperatures up to 200ºC and provides high tensile strength that guarantees long durability according to the most demanding industrial standards. The transport band is sewn with a removable closure for easy handling or replacement with another of different dimensions or characteristics.

The connection of this drying tunnel is three-phase (3 F + N + T), compensated at 3 kW per phase. Upon request, it can be produced for single-phase connection of the desired power up to a maximum of 9 kW..

The TS2500 is supplied fully wired and with the electrical panel ready to be hung in its final position on the tunnel structure itself. The whole set is supplied packed in a closed palletized wooden box (included in the price). Means of transport and lifting of the package may be necessary for handling during transport (pallet truck, forklift, etc.). It is a stackable package that minimizes the cost of transport. There is the option of supplying it assembled, although in this way the overall dimensions increase and make the cost of transport higher.

This product is available in stock for immediate delivery, 12-24 h.

- There is the possibility of acquiring the equipment assembly service. This assembly will always be carried out in our facilities and will cost €110. In this case, the disassembly and transport would be borne by the customer.

Data sheet