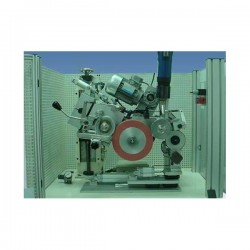

The development of this printing system is based on the indirect hollow-engraving procedure and was developed for the printing of cylindrical circular pieces or flat hollow bodies. The rotary pad printing mechanism operates by means of a cylinder shaped silicone pad attached to another cylindrical plate. The reasons for introducing and developing rotary pad printing in the field of labeling and decorations by direct printing for technical and packaging parts of all kinds are the following: Possibility of printing on difficult surfaces, such as low relief, Vaulted surfaces, extremely pronounced edges, uneven surfaces, etc., had been very difficult or absolutely impossible because of the decoration procedures used so far. High production speeds - approx. 20-30 meters / minute.

En muchos casos es notablemente más rápida que los procedimientos convencionales de decoración y rotulación (véanse los problemas arriba mencionados), con una calidad invariable de la impresión. Manejo simple de las máquinas, por lo que no se necesita un personal adiestrado. Dispositivo de cambio rápido para clichés de plástico en todos los mecanismos de impresión rotativa, tanto si son Horizontales como verticales. En casos de grandes cantidades de piezas a decorar, los mecanismos impresores operan con clichés cilíndricos fabricados en un acero especial bruñido 65rc. Para cantidades medianas e impresiones policromas se puede trabajar con una mayor comodidad con clichés de plástico sin una reducción de calidad. El usuario mismo puede hacerse estos clichés de plástico, para ello solo es necesaria una película positiva y agua templada. Así, los gastos de mantenimiento de la máquina de impresión rotativa por tampón son favorables y económicos.

En croma Ibérica ponemos a la disposición de nuestros clientes la posibilidad de realizar un renting de este equipo.

Loading...

Loading...