It has integrating heater and heater plate. To be safer and more useful with the uniform heating surface.

Adopt Teflon as antiseize coated layer for heating pad.

Electrical time control and signal indicator after the complete process.

Allows you to preset the desired temperature and this will automatically be regulated and kept within the desired working range.

Using the knob or located in the upper part of the press, we can adjust the closing height by adjusting the pressure and the distance depending on the thickness of the product to be ironed. Turning clockwise will decrease the height or pressure and turning counterclockwise will increase the closing pressure.

Allows you to control the ironing time. When the iron is turned on, the counter will be activated and after the preset time it will emit a sound warning of the end of the ironing time.

The base of the plate is covered with a 20 mm thick silicone rubber blanket. This will make it easier for the product to adapt to its entire surface and make an irregular homogeneous ironing with an unequaled quality.

To facilitate the use of the press and make the task of the iron operator lighter, it is equipped with a reinforced and economical handle that will facilitate the task during the operator's hours.

On one of the sides next to the ignition switch we will find the circuit breaker or thermal protector that will protect in cases such as connection of overloads to the network. In case of excess consumption, short circuit, or some anomaly, it must be used to reset the system.

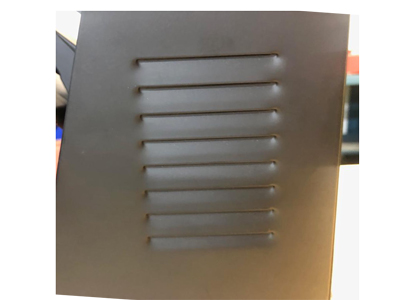

The iron is equipped with a cooling system, with which we will avoid overheating, and a stable temperature at work.

Data sheet

Loading...

Loading...