We offer the simple pelican screen printing arm as a solution for those professionals who are not dedicated to screen printing, but need to respond to specific screen printing requests. It is also a very suitable solution for small workshops that combine screen printing with other activities and usually respond to small screen printing requests.

The Pelican Silk-screen Printing Arm is manufactured from anti-corrosion treated steel and lacquered, which offers high strength and durability. In addition, a foot has been designed with the aim of keeping the Pelican Silk-screen Printing Arm stable at all times, a fundamental condition for obtaining perfect results and working comfortably.

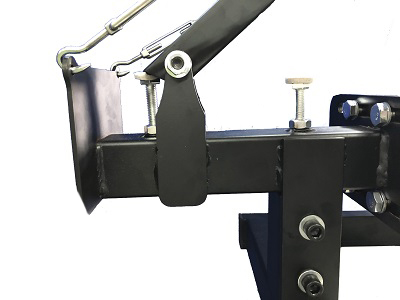

It has a wing nut system for easy placement of the screen printing. The mounted wing nuts ensure a strong hold of the screen so that the screen prints come out perfect.

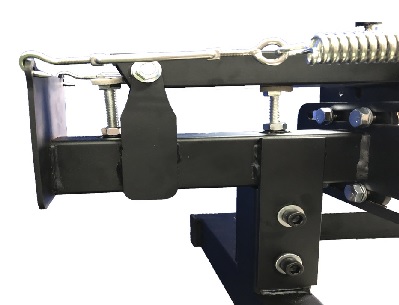

Normally, simple arms have a problem: When a large screen is placed, the arm cannot support the weight of it and falls on the garment, making the work very uncomfortable. The Pelican mounts some tensioners that allow to regulate the force that the arm must exert to hold frames of different sizes.

It has a system for regulating the parallelism between the base (garment to be printed) and the screen printing, as well as a system to adjust the base laterally (left and right). In this way, it is possible to adjust the optimal position of the screen and ensure uniform contact between the screen and the garment to be printed.

The distance regulator mounted on the Pelican allows you to adjust the distance between the screen and the garment to be screened printed. This allows for optimal results.

The Pelican comes disassembled in compact packaging to reduce transportation costs. Its assembly is so simple that it does not require any technical assistance. Learn how to assemble it in the video below.

Data sheet

Download

Manual pelicano

Download (207.88k) Loading...

Loading...

The Pelican Silk-screen Printing Arm is the perfect economical solution for one-off or short-run screen printing jobs.

More