Kraken Textile Printing Press Machine

The Kraken manual screen printing press machine is intended for professional users seeking maximum ergonomics, ease of use and rigidity. Also to professionals who respond to small or medium orders.

The price of the Kraken is tremendously contained considering the benefits it offers. It has been designed with the aim of offering a real solution that facilitates the access of new professionals to the personalization activity and improves the sector.

The Kraken manual screen printing octopus is delivered disassembled in several compact packages to reduce shipping costs as much as possible. It should be noted that the assembly of the octopus is very simple, and no technical assistance is needed.

The Kraken mounts aluminium bases for greater heat dissipation. When pre-curing on multicolour screen prints, wood bases tend to heat up and warp. As the screen approaches the base for the next printing, the radiated heat can dry the inks on the screen (especially water-based ones), irreparably affecting the quality of the serigraphs. With the aluminium bases, the effect is minimized, achieving better results.

In addition, the wooden bases tend to deform over time (due to the use and cleaning of the glues), which is not the case with aluminium bases.

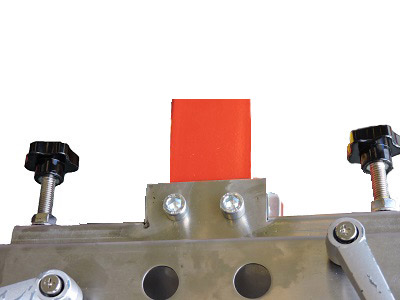

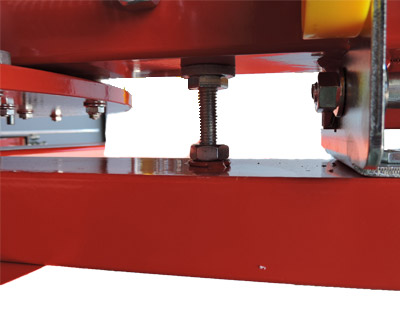

Kraken has a system that will allow you to level each of the bases for a precise fit at each workstation, allowing maximum print detail in all colours.

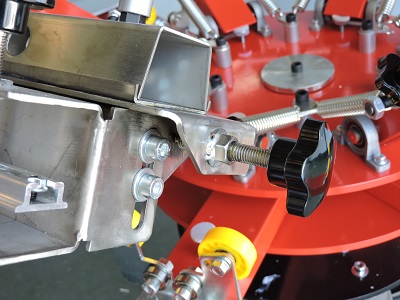

The Kraken screen printing octopus mounts a micro register on the 3 axes (x, y, z) in each of the arms. The register is adjusted manually, without the need for tools.

A double colour indexing system has been installed in the Kraken to guarantee perfect results in screen prints of more than one colour. This system keeps the arms stable in the correct position in each case in perpetuity over time.

You can adjust the height and parallelism of the display frame to the base at each station. This setting is important as it determines the amount of ink that will be transferred to the fabric and to obtain silkscreen prints with good definition and high opacity.

Throughout your professional activity, you will use different sizes of frames. The Kraken mounts a system that will allow you to adjust the screen's resting position according to its size and weight so that you can work comfortably, and the inks do not spill on the back of the frame. Fewer incidents during the printing process will make the time spent printing more efficient.

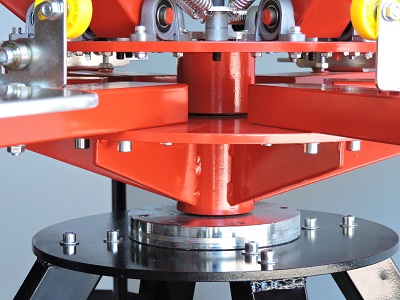

Thanks to a large double structure built in mechanized electro welded steel to achieve high rigidity and high durability. Equipped with double steel bearings for maximum rigidity and stability over time.

The design of the Kraken makes it very robust. It has a wide support bench for the set with wheels and a fixing system to move it and place it comfortably in the desired place. It also mounts a double machined turret with bearings to move the arms and bases smoothly.

The Kraken manual screen printing octopus is delivered disassembled in several compact packages to reduce shipping costs as much as possible.

The Kraken 4/4 is delivered in 1 palletized package. The weight is 150 Kg.

The Kraken 6/6 is delivered in 1 palatinate package. The weight is 190 Kg.

There is the possibility of acquiring the equipment assembly service. This assembly will always be carried out in our facilities and will cost €110. In this case, the disassembly and transport would be borne by the customer.

Data sheet

| Ref. | Brazos/Estaciones | Unit price | Buy |

|---|---|---|---|

| SS10327 | 4/4 |

€2,292.00

|

|

| SS10328 | 6/6 |

€2,920.00

|

|

|

Total:

0,0

All prices with tax excluded.

Tax rate: 21,0%. |

|||