The operation of the machine is carried out thanks to the special thermal head with CTS system which heat-perforates the fabric making a film. The system consists of applying an energy equivalent to 600dpi that excels in solid printing and a perforation density of 1,200dpi for detail work. In this process, a special (prepared) fabric is used, which allows for fine gradations in the printing and allows the creation of low-cost screens, fast even for the production of samples and small batches.

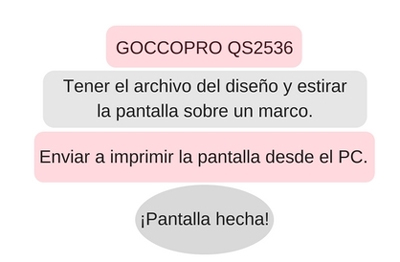

Goccopro QS2536 printing process. Simple, fast and effective in just 4 steps.

Goccopro collaborates in the participation of caring for the environment, since it consumes less electricity, does not generate wastewater and the use of solvents is not applied to make the screen. With a computer (PC) and the Goccopro you can create designs on screen printing screens without using polluting liquids.

The fabric is a special fabric, prepared to arrive and put on the frame without having to use solvents, liters of water, etc.

- Accurate image quality and accurate registration.

- System of dry thermal screens.

At Croma Ibérica we offer individualized services for each client, adapting to all their needs, for that reason we offer specialized training for each client. This is a training course on printing with Goccopro, intended for all those who need to print, personalize or decorate any type of product and lack experience in the printing process using Goccopro.

Contact us: mkt@cromaiberica.com

Training for use in our facilities is included in all equipment.

30 years of experience support our recommendation to carry out the training in our facilities for different reasons, but mainly because the people involved are fully dedicated to training, without external agents to interfere or interrupt, in addition to the fact that the people to train can see first-hand hand, other systems or tools that can complement the planned training and provide a broader knowledge of the process.

Data sheet

Loading...

Loading...

Goccopro QS 2536 is faster, more efficient and less costly. The new revolution in the manufacture of digital screens.