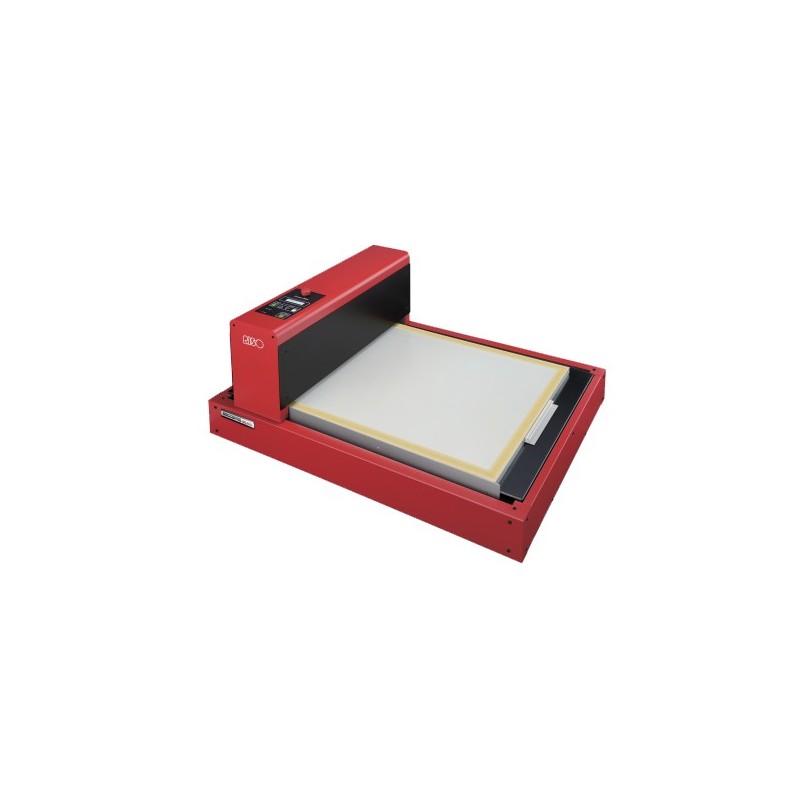

Goccopro QS200

Creating silkscreen screens for your work is not easy. It takes experience, knowledge and skills, and you are still forced to do multiple screens because mistakes are inevitable. Especially complicated is the case of multicolour serigraphs, where you have to make several screens for each of the colours and that they have the exact tension so that the overlap is perfect, and the colours do not mix. With the Goccopro QS 200 screen printing machine, you will create high resolution screen printing screens for multicolour screen printing without the possibility of errors and in just two minutes.

The operation of the Goccorpo QS 200 is simple, and no experience is required for the creation of silkscreen screens. First, the polyester fabric must be cut to the appropriate size for the screen frame to be used. Such a fabric is placed on the frame, stretched and placed on the machine. Automatically, Goccopro QS 200 prints the desired image sent to it in high resolution on the fabric (as simple as sending a document to the printer), generating the screen in a few minutes and without using reagents, photoliths or water. It would only be necessary to place the screen on the serigraphic octopus and apply the ink. The result is a silkscreen in one or more colours with a finish impossible to achieve with the traditional method.

The savings resulting from the use of the Goccopro QS 200 is significant. Remember that it is not necessary to use reagents, photoliths, emulsions or water. In addition, its speed of screen creation allows a notable saving in time and labour. Each screen created has a low cost: On average, for an A3 size screen, the screen would cost 5.50 euros. In addition, considering that the result allows accepting complex jobs unattainable with the traditional method, which allows the sale of jobs with great added value, it makes screen printing a more than profitable activity.

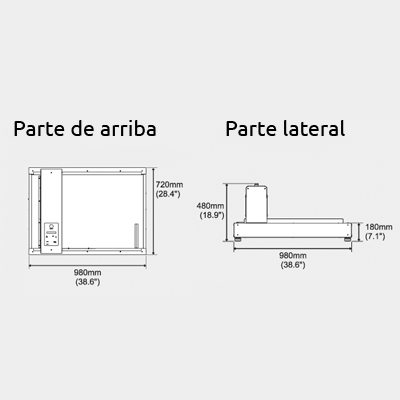

Goccopro QS 200 is a screen printing machine designed by the Japanese corporation Riso Kagaku and it is the first high resolution digital screen printing machine. The desired image is engraved on the polyester fabric using a thermal process that does not involve reagents or photolytes, so there is no need for a laboratory or dark room. It is possible to print screens of a maximum size of 420x620 mm from any image from any application and format (CorelDraw, Adobe Illustrator, Adobe Photoshop, PDF, Word, jpg, gif, etc.). It has a USB 2.0 interface. It is a perfect solution for any sector, such as advertising, communication, sportswear, workwear, textiles in general, etc.

Contact us: mkt@cromaiberica.com

Training for use in our facilities is included in all equipment.

30 years of experience support our recommendation to carry out the training in our facilities for different reasons, but mainly because the people involved are fully dedicated to training, without external agents to interfere or interrupt, in addition to the fact that the people to train can see first-hand hand, other systems or tools that can complement the planned training and provide a broader knowledge of the process.

Data sheet

Loading...

Loading...