Lógica Platform

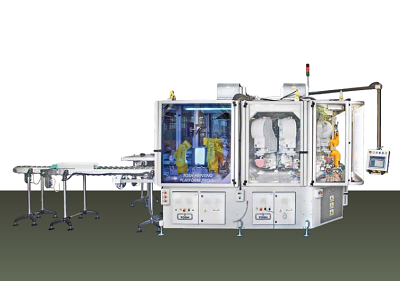

Modular, electrically operated pad printing machine.

Lógica Platform is a flexible pad printing machine, compatible with other complementary systems to obtain a complete solution with 100% autonomous operation within a production line:

It has been designed with high quality standards to ensure a long useful life and avoid the need for maintenance that interrupts production processes.

Lógica Platform has a series of characteristics that allow rapid production changes (in less than 1 minute):

The machine is faired and slightly pressurized to prevent the entry of dust particles or other objects that could alter the stamping result. It also has antimicrobial filters and a temperature maintenance system to maintain a clean and optimal environment.

The fairing and pressurization system prevent the escape of solvent vapors, maintaining a pleasant environment for the operator. In addition, it is a silent machine allowing its operation in any environment.

Model for printing 4-color cosmetic containers in various areas of the container with 4 print heads. 100% automatic loading and unloading of containers. Surface treatment prior to printing and printing quality control vision system.

Model for printing cologne containers for reference brands with 6 heads for 6-color printing. Fully automatic solution.

Model for customizing metal parts with double rotary table and UV drying. It has installed a vision system for printing quality control, automatic tampon cleaning and air treatment and cleaning system for extreme quality results.

Training for use in our facilities is included in all equipment.

30 years of experience support our recommendation to carry out the training in our facilities for different reasons, but mainly because the people involved are fully dedicated to training, without external agents to interfere or interrupt, in addition to the fact that the people to train can see first-hand hand, other systems or tools that can complement the planned training and provide a broader knowledge of the process.

Data sheet