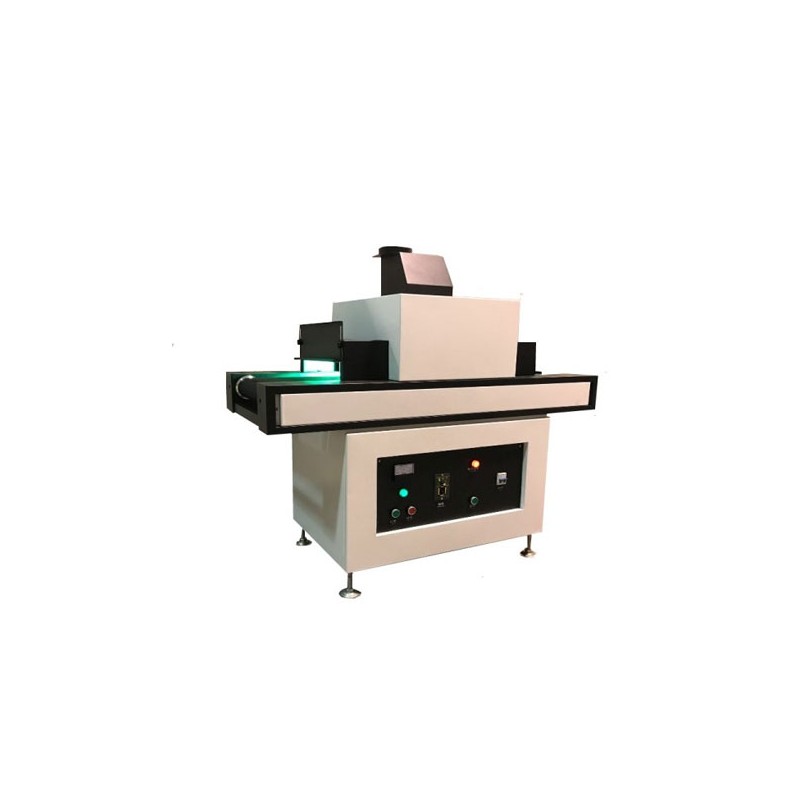

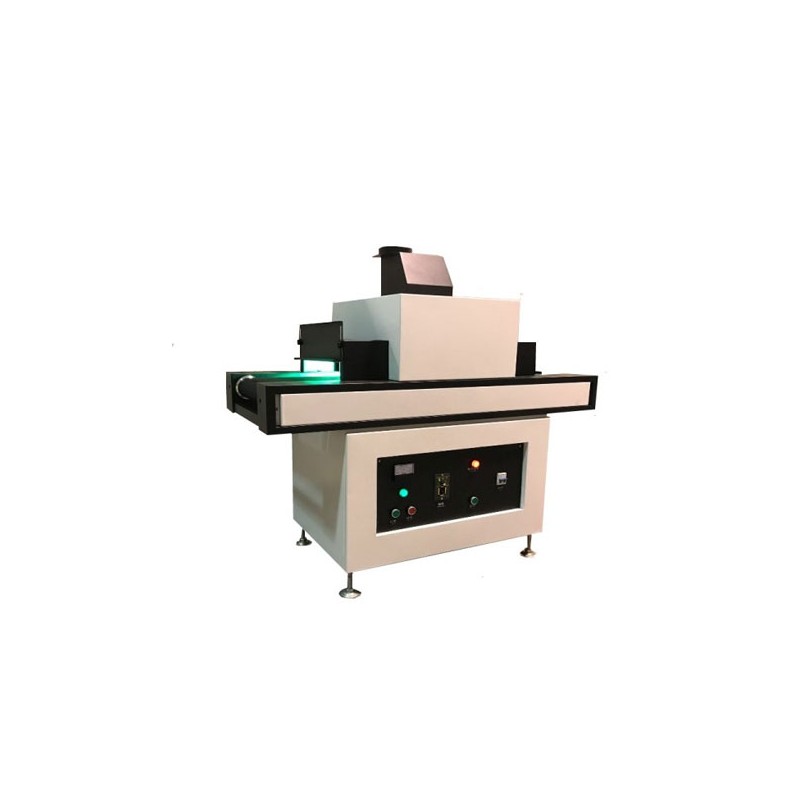

Structure in structural steel, electrowelded and varnished, they offer rigidity to the set so that the temperatures and work environments inside do not affect it over the years.

The unit is equipped with the latest generation electronic ballast, which offers a higher performance (in the order of 40% over the same traditional lamp) with its corresponding doping. It is also possible to carry out a linear electronic adjustment of the power, without steps and a permanent display of the configuration parameters of the lamp such as power, current and voltage.

High quality fiberglass reinforced Teflon conveyor belt guarantees high stability over time by minimizing the effects of UV radiation on it. This guarantees thousands of hours of operation without the need for periodic belt changes.

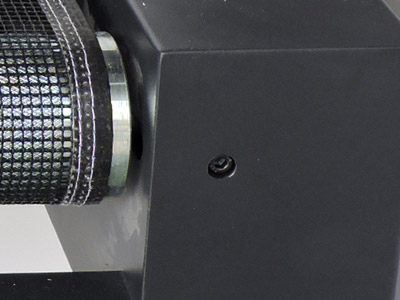

Easy to adjust the belt thanks to its externally accessible belt tensioners.

It offers a high power ventilation system to ensure efficient ventilation of the system and provide a clean work area close to the tunnel without harmful gases generated by the UV lamp.

The system makes it easy to regulate the distance between the product to be cured and the curing lamp. This allows the equipment to be adjusted to different product heights, also offering the reading of the height in mm so that it can be repeatable and reconfigurable with the different adjustments required by the different items to be treated.

Easy-to-read control panel with an indication of values important to the operator.

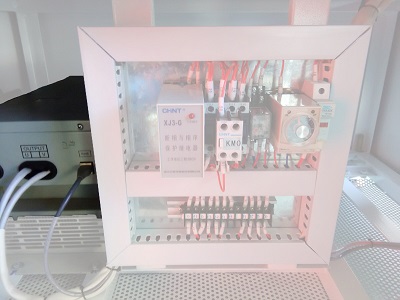

The equipment includes an electronic control of the correct assignment of the phases in the supply current. If they are not correctly connected, it makes it impossible to start the equipment, thus protecting the system against possible failures in the ventilation of the lamp, direction of rotation of the belt and electronic controller of the digital ballast of the lamp. It also has an integrated disconnector to be able to count on the total disconnection of the machine from the general installation in such a way that possible permanent residual currents of the control elements of the maneuver are avoided.

In addition, it has an emergency stop integrated into the structure of the machine for greater safety in operation.

Web speed display in real time, controlled by means of an encoder on the belt turning transmission shaft. In this way the job settings are easily identifiable and repeatable.

Display of the electronic controller of the UV lamp, with indications of the power, current and voltage in real time on the lamp terminals. We will then be able to know at all times the real values with which we are producing.

Electronic regulation of the absolute power of the lamp. By means of a potentiometer on the panel we can regulate from 20% to 100% of the possible radiation energy of the lamp. In conjunction with the real-time power display, we can regulate the energy in each job easily and intuitively without steps.

Thanks to the hour meter it is possible to have control over the hours of life of the lamp and anticipate the replacement of these during maintenance, thus avoiding inopportune incidents during production.

Wheels for easy location and light handling so that it is possible to move it to different production locations easily. They have built-in fixing legs to seat them in the work area.

Download

Loading...

Loading...