A-101CNC

One of the main attractions of this model is its great flexibility and elasticity, since by equipping the numerical control systems it allows to guarantee printing on any shape or part model.

In practice, there are really few cases where this advantage really becomes a real profitability since minimally short production batches of around 10,000 pieces make a system of these characteristics end up being slow to put on.

As a result of the experience with these models, we are committed to developing an application based on numerical control, but without the intention of making any type of shape.

One of the most interesting things about this machine is that it allows the screen printing of the entire article in a single print. It is especially designed for industrial productions and offers a high screen printing speed that is optimal for large productions (up to 2,100 pieces / hour). It also allows a wide range of sizes of pieces to be screen printed: For cylindrical pieces the printing diameter ranges between 20 - 100 mm and the length between 30 - 180 mm. For square, rectangular or irregular objects the print length ranges from 30 - 180mm and the width from 20 - 100mm.

Likewise, there are also a great variety of productive batches that focus the productions between 5000 and a maximum of 8000 pieces and this makes it especially interesting to have a system that is very fast to set up and that is very little exquisite when preparing. tooling.

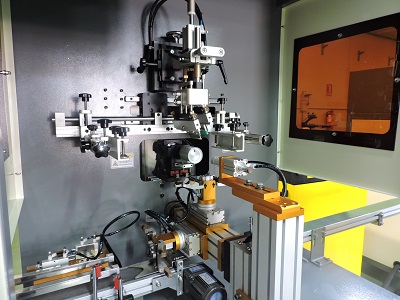

In this way, the A-101CNC equipment only equips two control axes, one for the rotation of the piece and the other for the movement of the screen. In this way, the transmission between what would traditionally be between gear and rack becomes an electronic cam.

This configuration is ideal for printing cylindrical containers or flat containers one or the other, but not both.

-Feeding band.

- Loading and unloading manipulator

-Download band

-Cylindrical screen printing head.

Trading A-101CNC is really easy. The machine is controlled and programmed from an operator accessible touch screen display. For the change of object to be printed it does not take more than 15 minutes for each of the colors. In addition, its operation is totally safe, as it complies with CE safety standards.

At croma Ibérica we offer our clients the possibility of renting this equipment.

Training for use in our facilities is included in all equipment.

30 years of experience support our recommendation to carry out the training in our facilities for different reasons, but mainly because the people involved are fully dedicated to training, without external agents to interfere or interrupt, in addition to the fact that the people to train can see first-hand hand, other systems or tools that can complement the planned training and provide a broader knowledge of the process.

Loading...

Loading...