A-201CNC

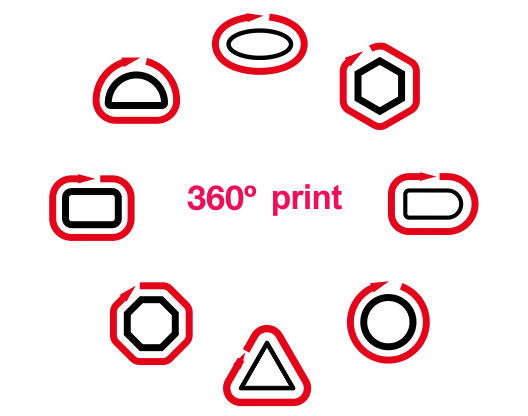

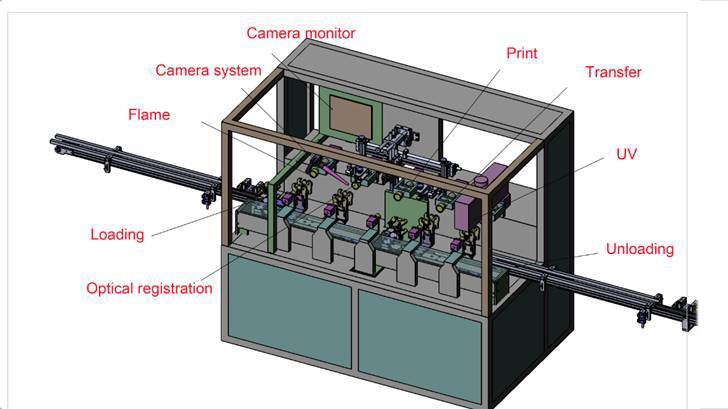

A-201CNC is an industrial screen printing machine designed to screen any glass item and any shape. One of the most interesting things about this machine is that it allows the screen printing of the entire article in a single print. It is especially designed for industrial productions and offers a high screen printing speed that is optimal for large productions (up to 2,100 pieces / hour). It also allows a wide range of sizes of pieces to be screen printed: For cylindrical pieces the printing diameter ranges between 20 - 100 mm and the length between 30 - 180 mm. For square, rectangular or irregular objects the print length ranges from 30 - 180mm and the width from 20 - 100mm.

One of the most interesting aspects of this machine is its modular manufacturing design, where up to 10 units can be installed in line for multi-color screen printing. The machine is prepared for the installation of a plasma flaming accessory to enhance the fixation of the ink on the glass. For drying and fixing the ink on the object, a UV LED or an electric UV system can be used.

A-201CNC allows fully automatic loading and unloading of articles or parts by means of a multi-axis servo robot. All the movements of the process are 100% automatic carried out by a servo robot: print head, rotation and positioning of the object, etc. One of the aspects that makes A-201CNC a highly efficient machine is that it is capable of screen printing on all sides of the object in a single cycle. It has a vision system with a camera for the rotation and positioning of the object for its screen printing, so the registration point is not necessary.

.jpg)

Operating A-201CNC is really simple. The machine is controlled and programmed from an operator accessible touch screen display. For the change of object to be printed it does not take more than 15 minutes for each of the colors. In addition, its operation is totally safe, as it complies with CE safety standards.

At croma Ibérica we offer our clients the possibility of renting this equipment.

Training for use in our facilities is included in all equipment.

30 years of experience support our recommendation to carry out the training in our facilities for different reasons, but mainly because the people involved are fully dedicated to training, without external agents to interfere or interrupt, in addition to the fact that the people to train can see first-hand hand, other systems or tools that can complement the planned training and provide a broader knowledge of the process.

Data sheet

Loading...

Loading...